How Eggs Are Produced: From Farm to Breakfast Table

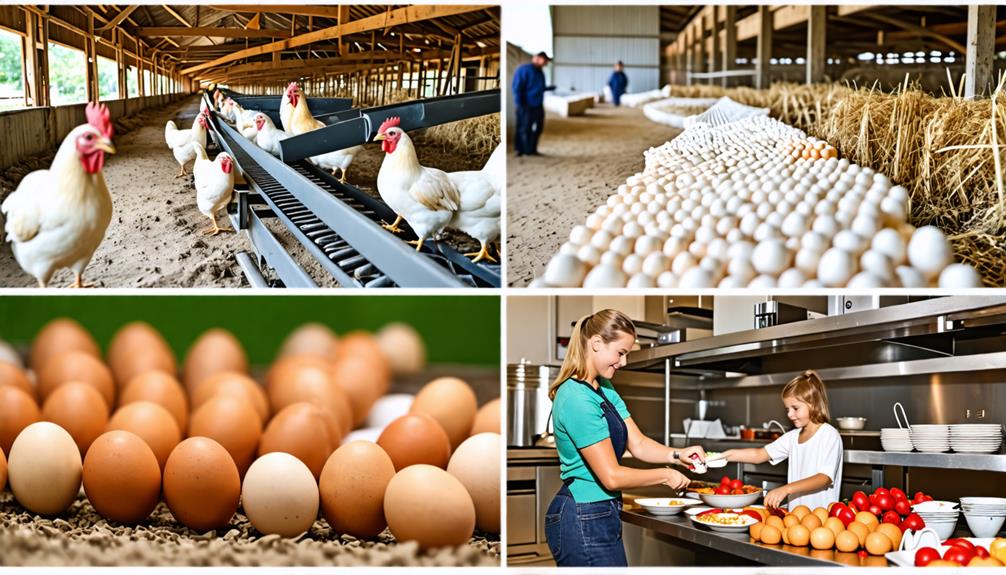

When you think about how eggs reach your breakfast table, you might not realize the detailed process behind each step. Eggs are collected from hens at Hertzfeld Poultry Farms, where 1.3 million hens lay about 100,000 eggs daily. Advanced robotic systems then sort and package these eggs. But what happens after the eggs are cleaned and graded? How do technological advancements and hen welfare practices ensure the eggs' quality? The journey of an egg is more complex than it seems.

Egg Production Overview

Hertzfeld Poultry Farms in Grand Rapids, Ohio, operates with 1,300,000 laying hens, making it a key player in egg production. As soon as the hens lay eggs, they roll onto a conveyor belt, starting their journey through the processing system. This immediate collection ensures efficient handling of about 100,000 eggs daily from the farm's eight barns.

Once on the conveyor belt, the eggs move to a central processing area where robotic systems sort them by size. These robots ensure uniformity and quality. The eggs are then cleaned, weighed, and packaged. This high-tech method boosts production efficiency and keeps the eggs fresh and safe.

After processing, eggs must be stored in a 42-degree cooler within 36 hours of laying to maintain freshness. Hertzfeld Poultry Farms usually cools the eggs in about one hour, preserving their quality and ensuring they reach customers in optimal condition. By following these steps, Hertzfeld Poultry Farms delivers fresh, high-quality eggs every time.

Egg Processing Steps

Egg processing begins with cleaning and disinfecting the eggs to meet USDA standards. The next step involves robotic systems that sort and weigh the eggs, removing any cracked ones. Finally, the eggs are packaged and stored in a cooler to maintain freshness.

Cleaning and Disinfection

In egg production, cleaning and disinfection are essential to ensure the eggs you eat are safe and high-quality. To meet USDA standards, eggs are washed with an organic citrus solution. This removes dirt and contaminants, making sure the eggs are clean before they reach your table.

After washing, the eggs go through a drying process and UV disinfection. These steps confirm that the eggs are sanitized and safe to consume. With about 100,000 eggs processed daily, maintaining high hygiene standards is crucial.

Here's what happens during the cleaning and disinfection phase:

- Organic Citrus Solution: Cleans eggs and removes contaminants.

- Drying Process: Ensures eggs are completely dry to prevent bacterial growth.

- UV Disinfection: Kills any remaining pathogens.

- Automated Systems: Reduce human contact, improving overall hygiene.

- Quality Control: Each egg is photographed to ensure only intact, clean eggs are packaged.

Following these steps ensures that when you crack open an egg, you're getting a product that's safe, clean, and of top quality.

Sorting and Weighing

Sorting and weighing eggs is crucial for ensuring a consistent product. After washing to meet USDA standards, the eggs move to the sorting stage. Here, advanced robotic systems take over, greatly improving efficiency. These systems can handle about 100,000 eggs daily, making sure each one is categorized by size and weight.

Automated machines scan and assess each egg, reducing human contact and lowering the risk of contamination. This ensures that when you buy a carton, you get eggs of uniform size. It's not just about convenience; it also maintains quality and safety.

Weighing is another key part of the process. The same robotic systems that sort the eggs also weigh them, ensuring they meet specific standards for different categories like small, medium, large, and extra-large. This detailed sorting and weighing process ensures that each carton contains eggs of similar size and weight, providing a consistent cooking and baking experience.

Once sorted and weighed, the eggs are ready for packaging and shipping to stores, arriving fresh on your breakfast table.

Packaging and Storage

After sorting and weighing, eggs proceed to packaging with minimal delay to preserve their freshness. This step is crucial for maintaining egg quality and safety.

First, eggs are washed with an organic citrus solution that meets USDA cleanliness standards. Then, they are dried and UV disinfected to remove any remaining bacteria. Quality control is strict; each egg is photographed and undergoes a tuning fork test to find any hairline cracks. Only the best eggs move on to packaging.

In the packaging stage, eggs are automatically placed into cartons, which minimizes human contact and reduces contamination risks. Each pallet holds 900 dozen eggs and is stored at a consistent 45°F to keep them fresh.

Key steps include:

- Organic citrus washing solution: Ensures USDA-standard cleanliness.

- UV disinfection: Adds extra safety.

- Tuning fork test: Detects hairline cracks.

- Automatic carton placement: Minimizes human contact.

- Pallet storage at 45°F: Maintains freshness.

After processing, eggs are moved to a 42-degree cooler within 36 hours of laying. They reach stores within 1 to 5 days, ensuring you get the freshest eggs possible.

Storage and Distribution

Ensuring the freshness and quality of eggs is essential. Eggs should be placed in a 42-degree cooler within 36 hours of laying. Usually, it takes about an hour to get the eggs into storage after they're laid. Once cooled, they are cleaned, sorted, weighed, and packaged. This efficient process allows about 100,000 eggs to be prepared daily for distribution.

After packaging, eggs are kept in cool environments to maintain freshness. Distribution happens quickly, ensuring eggs reach stores within 1 to 5 days after laying. Trucks, which can transport between 10,000 to 20,000 dozen eggs per trip, are crucial in this process. They move eggs from processing plants to distribution centers and then to grocery stores.

From nest to breakfast table, the process takes around 25 days. Following these storage and distribution protocols ensures that you get fresh, high-quality eggs. The USDA recommends consuming eggs within this timeframe for the best quality. So, when you pick up a carton, you can be confident in its freshness and quality.

Technological Advancements

Recent technological advancements in egg production have transformed the industry. Robotic systems now sort and package eggs, increasing efficiency and enabling the processing of 100,000 eggs daily with high accuracy. These innovations reduce manual labor and require a skilled workforce proficient in robotics and engineering.

If you are in the egg production industry, consider investing in robotic systems to boost efficiency. Train your staff in robotics and engineering to handle the new technology effectively. This will not only streamline operations but also ensure that your workforce is prepared for future advancements.

Robotics Enhancing Efficiency

In recent years, advanced robotics have greatly improved egg production facilities, making them much more efficient. These facilities can now process up to 100,000 eggs each day, a significant increase from the past. By automating key tasks like washing, sorting, and packaging, operations run smoothly from 7 am to 3 pm, reducing human contact and lowering contamination risks.

Robotic systems do more than just speed up the process; they ensure eggs are sorted by size and packaged correctly, maintaining high hygiene and quality standards. This technology shift has also changed the agricultural workforce, creating opportunities for people with skills in robotics and engineering.

Here's how robotics enhance efficiency:

- Increased daily processing capacity: Up to 100,000 eggs.

- Enhanced hygiene: Less human contact reduces contamination risks.

- Precision sorting and packaging: Ensures consistent quality.

- Streamlined operations: Efficient workflows from 7 am to 3 pm.

- Broader workforce opportunities: Attracts individuals with non-agricultural backgrounds.

These advancements make the egg production process faster and more reliable, setting new industry standards.

Advanced Sorting Systems

Advanced Sorting Systems at Hertzfeld Poultry Farms significantly boost productivity. These systems use robotic technology to sort 100,000 eggs daily by size and package them into cartons. This increases efficiency and accuracy, helping egg farmers meet high consumer demand.

Robotic systems minimize human contact during packaging, reducing the risk of contamination and enhancing food safety. Automated candling machines also work with these sorting systems to check the internal quality of eggs. This ensures only the best eggs reach consumers.

Technological upgrades have improved production, allowing Hertzfeld Poultry Farms to process eggs faster while meeting USDA cleanliness standards. This means consumers get fresher, safer eggs without sacrificing quality.

Operating and maintaining these advanced systems require skills in robotics and engineering. This creates new career opportunities in agriculture, enabling egg farmers to work with the latest technology.

Educational Initiatives

GrowNextGen is enhancing poultry education through various initiatives that highlight the egg production process. Collaborating with the Ohio Poultry Association, these efforts include diverse outreach activities to help communities understand the egg industry better.

Key components of these initiatives are:

- Teacher Events: Workshops and seminars educate teachers about egg production so they can pass this knowledge to their students.

- Virtual Field Trips: Online tours of egg farms and processing facilities show students the entire egg production chain.

- Webinars: Online seminars cover various egg-related topics, sparking student interest in agricultural careers.

- Career Focus: Highlighting career opportunities in agriculture, with a focus on the role of technology in egg production.

- Community Outreach: Programs engage local communities, helping them understand the egg industry's significance.

These initiatives aim to improve educational outcomes and inspire students to consider careers in agriculture.

Hen Welfare Practices

Ensuring the welfare of hens is crucial in egg production. Over 80% of U.S. egg-laying hens follow United Egg Producers (UEP) Certified guidelines, showing the industry's commitment to hen welfare. These guidelines set specific standards to improve hen well-being.

Hen welfare practices ensure continuous access to nutritious feed and clean water, which supports their health and longevity. Egg farmers follow best management practices to maintain disease-free environments, which is essential for the hens' physical and mental health.

Reducing stress is also important in hen welfare. Farmers provide enriched housing with perches and private areas for laying eggs. This improves hen comfort and reduces stress levels. Farmers also monitor the hens' health and comfort daily.

These practices ensure hens live in healthy, comfortable conditions, which improves the quality of the eggs they produce. By focusing on hen welfare, the egg industry shows a strong commitment to ethical and sustainable farming.

Cleaning and Grading

When eggs arrive at the processing facility, they go through a thorough cleaning process using specialized equipment. This equipment gently washes away dirt and contaminants, ensuring the eggs are safe to eat without compromising their structure. After cleaning, the eggs are graded based on size, weight, and quality.

During grading, the eggs undergo a candling process. This step involves shining a light through the eggs to check their interior quality. Automated candling machines make this step efficient by quickly spotting any defects. Only high-quality eggs move forward to packaging. Here's how the cleaning and grading process works:

- Specialized cleaning equipment: Removes dirt and contaminants without damaging the eggs.

- Candling process: Uses light to assess the interior quality of eggs.

- Automated candling machines: Increase efficiency and accuracy, identifying substandard eggs.

- Grading criteria: Sorts eggs by size, weight, and quality to meet consumer expectations.

- Uniform products: Only eggs that meet all standards are packaged for sale.

This method ensures that only the best eggs reach consumers, maintaining high standards for safety and quality.

Retail and Consumer Choices

When you browse the egg aisle at your local grocery store, you will see many options. These include conventional, organic, and free-range eggs, each produced differently. Labels give important details, such as whether the eggs are refrigerated. This is crucial for maintaining their quality and safety.

Eggs typically move from farm to store in about 25 days. Cartons have a Best By date to help you judge freshness. This ensures you get the best quality. Stores display eggs prominently and store them correctly, showing their commitment to food safety.

To help you choose wisely, information about egg categories and production methods is easy to find. Social media and other sources can teach you about proper egg handling and storage at home. This improves your food safety practices. By knowing these details, you can pick eggs that fit your dietary needs and ethical values. This ensures a safe and satisfying addition to your breakfast table.