How Egg Yolks Are Used in Industrial Adhesive Production

Egg yolks serve as powerful natural emulsifiers in industrial adhesive production thanks to their unique proteins and phospholipids. You'll find manufacturers using specialized processing methods, like high-pressure homogenization at 60-120 bar, to break down the yolk's components for ideal binding strength. The addition of sugars, salts, and amino acids enhances thermal stability and adhesive performance. While egg-based adhesives offer superior strength and sustainability, understanding their molecular properties accesses their full potential.

The Science Behind Egg Yolk Emulsification

Ever wonder how eggs help create industrial adhesives? The secret lies in egg yolks and their exceptional emulsifying properties. When you examine the characteristics of egg yolk, you'll find it's a natural powerhouse for blending substances that typically don't mix, like oil and water.

The yolk contains two key components that make this possible: insoluble protein aggregates called granules and specialized lipoproteins in the plasma (the clear yellow fluid). You'll find these elements work together to create stable mixtures essential for adhesive production. The effectiveness of this process can be enhanced by adding sugar, salt, or amino acids, which augment the yolk's thermal tolerance. Modern techniques like high-pressure processing help preserve these precious emulsifying properties while maintaining the structural integrity of the yolk's components. Thanks to their high-quality protein content of 6 grams per egg, yolks provide exceptional binding strength in adhesive applications.

Key Components of Egg Yolk in Adhesive Manufacturing

The molecular composition of egg yolk delivers a powerful punch in adhesive manufacturing. You'll find several key components that make egg yolk-based adhesives highly effective. The phospholipids serve as natural emulsifiers, helping to stabilize the adhesive formulation and ascertain consistent performance.

Two essential proteins, livetin and phosvitin, work together to provide both adhesive strength and cohesive properties. The lipoproteins enhance the adhesive's ability to wet surfaces and create stronger bonds.

You'll also benefit from the natural lecithin content, which optimizes the viscosity and flow characteristics of the final product. These components work synergistically, making egg yolk a crucial ingredient in industrial adhesive production. Their unique emulsifying and binding capabilities contribute to creating high-performance adhesives that meet various manufacturing needs. Similar to their role in traditional baked goods, eggs provide essential structure and binding properties that make them invaluable in adhesive manufacturing.

Processing Methods for Industrial Egg Yolk Applications

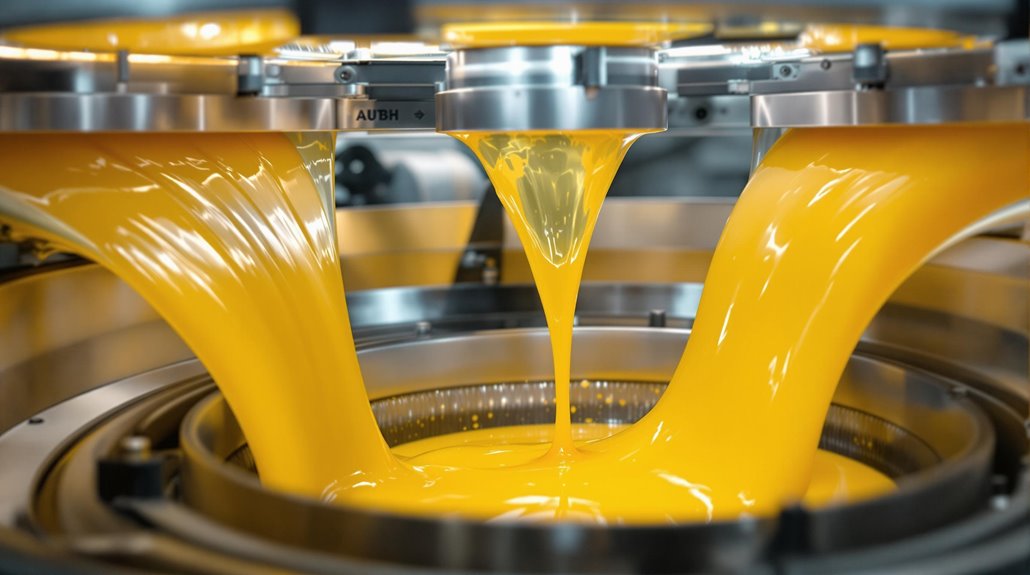

When processing egg yolks for industrial adhesives, manufacturers employ several specialized techniques to maximize their binding properties. In industrial food production, precise control over processing methods guarantees optimal performance of egg yolks in adhesive formulations.

- Homogenization at 60-120 bar pressure breaks down particles, creating a smooth consistency that's essential for uniform adhesive properties

- Non-thermal processing techniques preserve the yolks' natural emulsifying capabilities, avoiding the negative effects of heat treatment

- Strategic addition of ingredients like sugars, salts, and amino acids enhances the thermal stability and binding performance

These carefully controlled processing methods ensure you'll get consistent, high-quality adhesives that maintain the egg yolks' natural binding properties while meeting industrial manufacturing standards.

The binding strength of adhesives is enhanced by incorporating calcium carbonate compounds similar to those found naturally in eggshells.

Optimizing Egg Yolk Performance in Adhesive Formulations

Successful optimization of egg yolk performance in adhesive formulations relies heavily on understanding its unique molecular properties. You'll need to carefully balance the ratio of LDL and HDL components to achieve ideal adhesive strength and water resistance in your industrial applications.

When you're working with whole egg components, you can enhance the performance through specific processing techniques. Homogenization and thermal treatments will help you modify the egg yolk's emulsifying properties and rheological behavior to match your adhesive requirements. By leveraging the natural emulsifying power of phospholipoproteins, you'll create adhesives with superior spreadability and tack.

The colloidal structure of egg yolk makes it particularly versatile, allowing you to develop sustainable adhesive solutions that often outperform synthetic alternatives in regards to overall adhesive effectiveness.

Benefits and Limitations of Egg-Based Adhesives

Modern egg-based adhesives offer forceful advantages alongside notable limitations for industrial applications. As a binding agent, egg yolk delivers impressive performance through its natural proteins and lipids that create stable, flexible bonds. You'll find these adhesives particularly appealing for their environmental benefits.

Key advantages include:

- Superior adhesive strength and flexibility compared to synthetic options

- Natural emulsification properties that enhance stability

- Complete biodegradability that reduces environmental impact

However, you'll need to take into account some drawbacks when choosing egg-based adhesives. The seasonal nature of egg production can disrupt manufacturing schedules, while limited heat and moisture resistance may restrict their use in certain applications. Despite these constraints, egg yolk adhesives remain a preferred choice when you're prioritizing sustainability and natural bonding solutions.